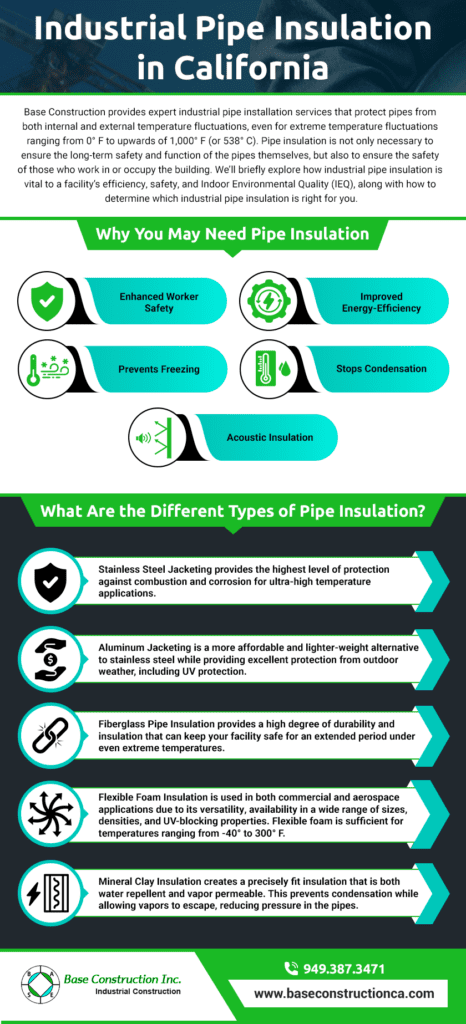

Base Construction provides expert industrial pipe installation services that protect pipes from both internal and external temperature fluctuations, even for extreme temperature fluctuations ranging from 0° F to upwards of 1,000° F (or 538° C). Pipe insulation is not only necessary to ensure the long-term safety and function of the pipes themselves, but also to ensure the safety of those who work in or occupy the building. We’ll briefly explore how industrial pipe insulation is vital to a facility’s efficiency, safety, and Indoor Environmental Quality (IEQ), along with how to determine which industrial pipe insulation is right for you.

Why You May Need Pipe Insulation

There are numerous advantages to expertly installed pipe insulation, and below are just some of the key benefits:

- Enhanced Worker Safety. Those working in the nearby area will be protected from injury, enabling them to work in greater comfort and peace of mind. Industrial pipe insulation also greatly reduces workplace injuries.

- Improved Energy-Efficiency. Our thermal pipe insulation material prevents exterior heat transfer away from the pipes, which significantly cuts down on wasted energy and heating costs.

- Prevents Freezing. In below-freezing environments, it’s crucial to keep the contents of pipes from freezing, which can easily cause property damage that may go undetected until after a significant amount of water damage occurs.

- Stops Condensation. Unchecked pipe condensation can lead to rust and health-damaging mold. Even when temperature extremes aren’t an issue, pipe insulation may be necessary to prevent condensation by regulating the temperature of the pipe.

- Acoustic Insulation. Pipe insulation materials can also be chosen for their high-level noise-reducing qualities in buildings such as theaters or medical facilities where the control of noise levels is important. Pipe insulation can stop sound vibrations from traveling along pipes into other parts of the building while keeping vibrations from traveling into adjacent flooring or wall materials.

What Are the Different Types of Pipe Insulation?

To achieve the right combination of features, such as those described above, Base Construction provides many different types of industrial pipe insulation materials to choose from:

- Stainless Steel Jacketing provides the highest level of protection against combustion and corrosion for ultra-high temperature applications.

- Aluminum Jacketing is a more affordable and lighter-weight alternative to stainless steel while providing excellent protection from outdoor weather, including UV protection.

- Fiberglass Pipe Insulation provides a high degree of durability and insulation that can keep your facility safe for an extended period under even extreme temperatures.

- Flexible Foam Insulation is used in both commercial and aerospace applications due to its versatility, availability in a wide range of sizes, densities, and UV-blocking properties. Flexible foam is sufficient for temperatures ranging from -40° to 300° F.

- Mineral Clay Insulation creates a precisely fit insulation that is both water repellent and vapor permeable. This prevents condensation while allowing vapors to escape, reducing pressure in the pipes.

Beyond our expertise with the material properties of pipe insulation products, we also create custom, form-fitting pipe-insulation shapes that effectively cover pipes of any kind. For pipes that are exposed to view, we can even provide All-Service Jacket insulation for a cosmetic appeal that gets the job done.

Why Is It Important To Insulate Pipes?

Industrial settings that require the use of extremely hot liquids carry a great risk of injury to your employees as well as damage to your equipment. Insulating pipes also lowers maintenance needs by reducing accumulated moisture. This further limits injury and property destruction by eliminating slip hazards and water damage that are common with unchecked pipe condensation.

The regulation of temperatures is another important reason to insulate pipes, which not only helps the environment but cuts down on your facility’s energy bills. Beyond just preventing direct-contact injuries, pipe insulation also ensures that the environment is at a more consistent and comfortable ambient temperature, enabling your employees to work more efficiently. During the colder months, pipe insulation prevents pipes from freezing, which leads to complicated and expensive pipe repairs that could stop your facility from functioning.

What Are the Best Materials for Pipe Insulation?

The most common pipe-insulation materials include fiberglass, foam, mineral wool, and Calsil. When researching how to insulate industrial pipes, selecting the right materials requires extensive knowledge of pipe insulation materials as well as a thorough understanding of the conditions particular to your facility. Selecting industrial pipe insulation types will depend on establishing a close relationship with Southern California’s most skilled industrial pipe-insulation contractor. We are committed to showing you the options available to you and helping you determine the perfect solution for your pipe-insulation needs.

Choose Base Construction For Your Pipe Insulation Needs

Base Construction provides a variety of pipe installation and maintenance services, including pipe insulation, heat tracing, process piping, pipe-route design, and more. In our over 90 years of combined experience, we’ve led over 5,000 projects to completion while ensuring an impeccable safety record. We are fully licensed and certified and, simply put, our work isn’t done until our customers are fully satisfied.

With a commitment to excellence at every level, we strive to help our clients succeed and achieve the highest efficiency possible even long after our work is complete. If you have any questions about industrial pipe insulation or would like to receive a quote, feel free to contact us online or call us at 949.387.3471.