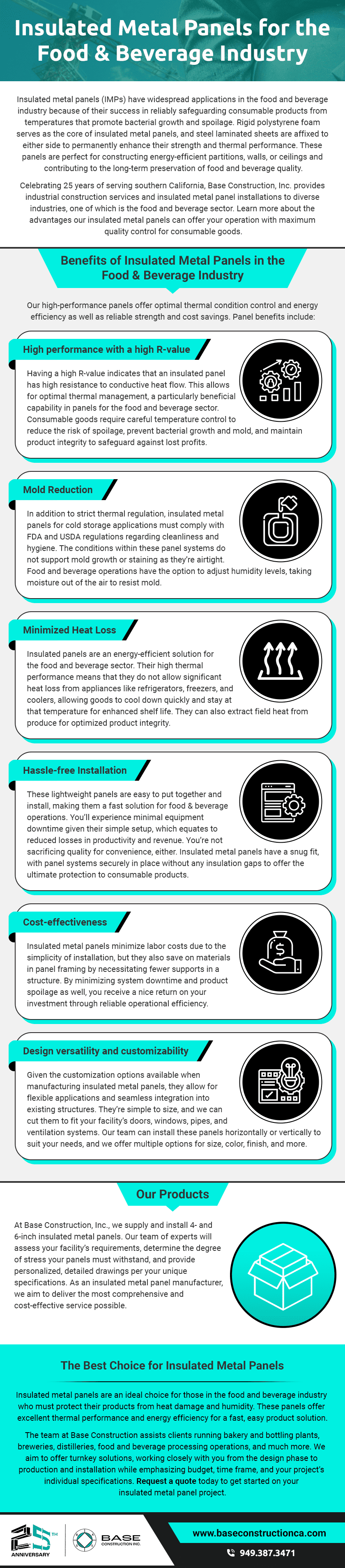

Insulated metal panels (IMPs) have widespread applications in the food and beverage industry because of their success in reliably safeguarding consumable products from temperatures that promote bacterial growth and spoilage. Rigid polystyrene foam serves as the core of insulated metal panels, and steel laminated sheets are affixed to either side to permanently enhance their strength and thermal performance. These panels are perfect for constructing energy-efficient partitions, walls, or ceilings and contributing to the long-term preservation of food and beverage quality.

Celebrating 25 years of serving southern California, Base Construction, Inc. provides industrial construction services and insulated metal panel installations to diverse industries, one of which is the food and beverage sector. Learn more about the advantages our insulated metal panels can offer your operation with maximum quality control for consumable goods.

Benefits of Insulated Metal Panels in the Food & Beverage Industry

Our high-performance panels offer optimal thermal condition control and energy efficiency as well as reliable strength and cost savings. Panel benefits include:

- High performance with a high R-value. Having a high R-value indicates that an insulated panel has high resistance to conductive heat flow. This allows for optimal thermal management, a particularly beneficial capability in panels for the food and beverage sector. Consumable goods require careful temperature control to reduce the risk of spoilage, prevent bacterial growth and mold, and maintain product integrity to safeguard against lost profits.

- Mold reduction. In addition to strict thermal regulation, insulated metal panels for cold storage applications must comply with FDA and USDA regulations regarding cleanliness and hygiene. The conditions within these panel systems do not support mold growth or staining as they’re airtight. Food and beverage operations have the option to adjust humidity levels, taking moisture out of the air to resist mold.

- Minimized heat loss. Insulated panels are an energy-efficient solution for the food and beverage sector. Their high thermal performance means that they do not allow significant heat loss from appliances like refrigerators, freezers, and coolers, allowing goods to cool down quickly and stay at that temperature for enhanced shelf life. They can also extract field heat from produce for optimized product integrity.

- Hassle-free installation. These lightweight panels are easy to put together and install, making them a fast solution for food and beverage operations. You’ll experience minimal equipment downtime given their simple setup, which equates to reduced losses in productivity and revenue. You’re not sacrificing quality for convenience, either. Insulated metal panels have a snug fit, with panel systems securely in place without any insulation gaps to offer the ultimate protection to consumable products.

- Cost-effectiveness. Insulated metal panels minimize labor costs due to the simplicity of installation, but they also save on materials in panel framing by necessitating fewer supports in a structure. By minimizing system downtime and product spoilage as well, you receive a nice return on your investment through reliable operational efficiency.

- Design versatility and customizability. Given the customization options available when manufacturing insulated metal panels, they allow for flexible applications and seamless integration into existing structures. They’re simple to size, and we can cut them to fit your facility’s doors, windows, pipes, and ventilation systems. Our team can install these panels horizontally or vertically to suit your needs, and we offer multiple options for size, color, finish, and more.

Our Products

At Base Construction, Inc., we supply and install 4- and 6-inch insulated metal panels. Our team of experts will assess your facility’s requirements, determine the degree of stress your panels must withstand, and provide personalized, detailed drawings per your unique specifications. As an insulated metal panel manufacturer, we aim to deliver the most comprehensive and cost-effective service possible.

The Best Choice for Insulated Metal Panels

Insulated metal panels are an ideal choice for those in the food and beverage industry who must protect their products from heat damage and humidity. These panels offer excellent thermal performance and energy efficiency for a fast, easy product solution.

The team at Base Construction assists clients running bakery and bottling plants, breweries, distilleries, food and beverage processing operations, and much more. We aim to offer turnkey solutions, working closely with you from the design phase to production and installation while emphasizing budget, time frame, and your project’s individual specifications. Request a quote today to get started on your insulated metal panel project.