Process piping is an efficient method of transporting raw materials in manufacturing and industrial applications. Process piping systems are different from conventional plumbing systems designed to transport water and wastewater. Facilities must pay close attention to the piping and fitting materials, along with the installation and maintenance of the system to maintain optimal performance.

What Is Process Piping?

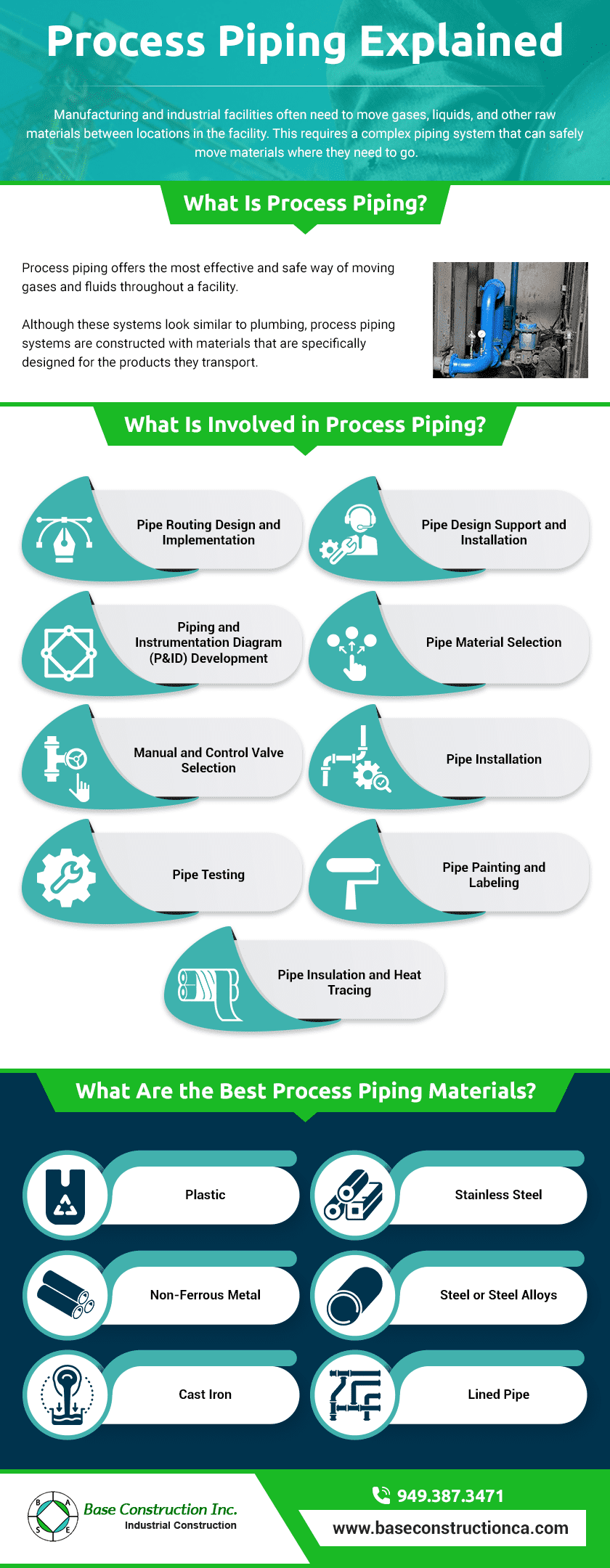

Manufacturing and industrial facilities often need to move gases, liquids, and other raw materials between locations in the facility. This requires a complex piping system that can safely move materials where they need to go. Process piping offers the most effective and safe way of moving gases and fluids throughout a facility. Although these systems look similar to plumbing, process piping systems are constructed with materials that are specifically designed for the products they transport.

What Is Involved in Process Piping?

Process piping requires several considerations to ensure the piping efficiently and safely transports raw materials. Constructing a process piping system typically involves:

- Pipe routing design and implementation. The piping system should be designed to efficiently route materials to the necessary locations. It also requires the proper implementation of pipes and components.

- Pipe design support and installation. Work with an experienced company that can provide design support and installation services for your process piping system.

- Piping and instrumentation diagram (P&ID) development and implementation. A P&ID maps the various piping and components that are present in your process piping’s flow process. This provides a graphic representation of your system’s details, schematics, and more.

- Pipe material selection. Choose the best construction materials for your process piping system based on the type of materials it will be transporting.

- Manual and control valve selection. Control valves and manual valves are also crucial components for regulating pressures and flows in the process piping system.

- Pipe installation. To ensure optimal effectiveness and efficiency, work with a partner that has extensive experience in installing these systems.

- Pipe testing. The piping must undergo rigorous testing for safety and functionality.

- Pipe painting and labeling. Painting and labeling are crucial for indicating and differentiating the differing piping throughout your system.

- Pipe insulation and heat tracing. Insulation or heat tracing may be necessary to keep the piping and its contents at a specific temperature.

At Base Construction, we can provide all of the above-mentioned services to ensure the best possible process piping system for your facility.

What Are the Best Process Piping Materials?

Determining the best material for your process piping systems depends on the application. The pipes’ ability to withstand the fluid or gas they are transporting is crucial. For example, saltwater and ammonia can be corrosive and would require process piping constructed with corrosion-resistant materials such as non-ferrous metals and plastics. Other factors that contribute to material selection include temperature and pressure.

The most popular materials for process piping include:

- Plastic. A wide range of plastic materials can be used for process piping, such as PVC, polypropylene, polyethylene, and ABS. Depending on which plastic you choose, these materials can offer temperature and corrosion resistance.

- Non-ferrous Metals. Non-ferrous metals, such as brass, aluminum, and copper, are ideal for applications requiring corrosion resistance and the ability to withstand high pressures.

- Steel or Steel Alloys. The thickness of steel as well as its ability to withstand high pressures makes it an ideal piping material for facilities that need to transport highly pressurized raw materials.

- Cast Iron. Cast iron is a long-lasting and corrosion-resistant material that is most suitable for underground piping systems

- Lined Pipe. Lined pipe is an economical option offering high strength and resistance to temperatures and corrosion. This is the most recommended material for fluid handling systems.

Base Construction’s Process Piping Capabilities

At Base Construction, Inc., we have over 90 years of combined experience in process piping. We can work with our customers to design and install the best process piping system for their needs. We also offer services such as painting, labeling, testing, material selection, support, and more. With a dedication to quality and maintaining safe practices in the workplace, we can deliver process piping systems that comply with OSHA and state regulations. Contact us today to learn more about our capabilities or request a quote to get started.