In Part 1 of our Safety Series, we examined the importance of safety guards for rotating equipment. Now that we know how they protect us let’s take a step back and see why these rails are safety essentials in the construction industry.

While it is impossible to eliminate all risks as industrial contractors, including process piping to structural steel fabrication and mechanical equipment installation, we strive to raise industry awareness about staying ahead of workplace risks.

With this in mind, we bring you the second installment of our three-part safety series: Why Roof Guard Rails are Safety Essentials.

Meeting OSHA and Internal Program Standards

At any construction company, the business should be Occupational Safety and Health Administration (OSHA) compliant. OSHA is part of the U.S. Department of Labor program, and here at Base, we take those regulations extremely seriously within our daily operations.

Not only is it important to follow OSHA standards, but CAL-OSHA, a client specific safety initiative, as well. Internally, we have chosen to provide a cohesive Injury and Illness Prevention Program (IIPP) of our own. This program keeps our staff accountable in our best effort to complete every job safely. Our company operates on the principle that safety is paramount. Direct results from our IIPP include both quality and successful project completion. We recommend any/all companies within the industrial industry follow in our footsteps to create a strong and effective internal safety program.

Safety Measures for Preventing Falls

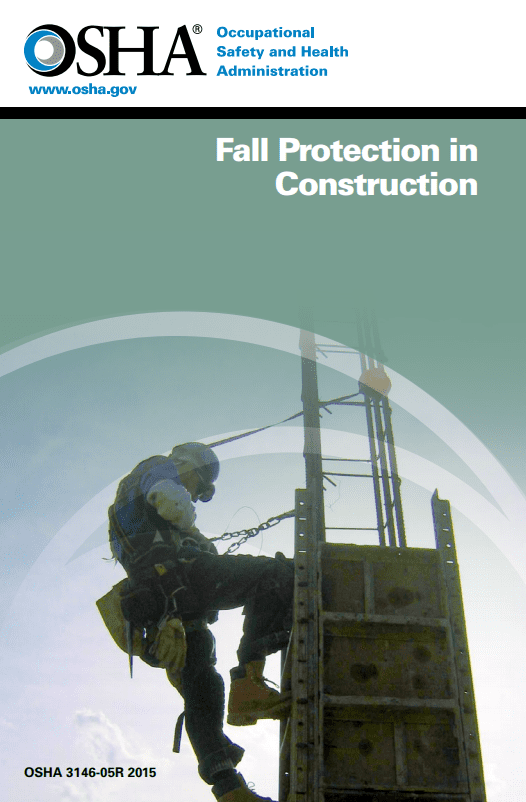

OSHA’s Fall Protection in Construction manual outlines 29 CFR 1926.502(b), pertaining to federal fall protection criteria and practices. Guardrail systems go around roof openings and at the roof perimeter.

As an industrial contractor, we recommend using guard rail systems on construction sites to prevent workers from falling to lower dangerous risk levels in hopes that more industry members will follow suit. The temporary roof guards can attach to rafters or other structural beams. There are also weighted portable guardrails, as seen here.

Guard Rail System Standards

If you decide to set up a guardrail system to protect workers in construction zones from fall hazards, you must adhere to OSHA’s federal guard rail system rules for accurate setup and proper implementation. For example, guard top rails and midrails must be at least 1/4 of an inch nominal diameter or thickness to prevent scratches and cuts. Other OSHA criteria pertain to the amount of force the guardrail system can withstand, the height and placement of midrails, and how to enact screens, mesh, and other structural members.

Looking Out for Our Workers

As an industry leader and employer, it is imperative that you look out for employee safety, including methods like fall protection measures, guardrail systems, and adhering each to OSHA and internal company requirements and standards.

Be sure to follow our Base Construction blog, so you know when the third and final part of our safety series goes live. We will be taking a brief pause in October for National Manufacturing Day on October 6th.

Beyond our monthly blog, easily stay up to date by following us on LinkedIn and Twitter too. For your next industrial project, contact us to manage and handle all of your industrial needs. We look forward to speaking with you soon!